Vista® Switchgear, Protection-and-Control Scheme Help to Modernize Smelter Facility

CASE STUDY: VISTA® UNDERGROUND DISTRIBUTION SWITCHGEAR

S&C Featured Solution: Remote-Supervisory Vista® Underground Distribution Switchgear

Location: Canada

Six-way Remote Supervisory Vista® Underground Distribution Switchgear during factory-acceptance testing.

Customer Challenge

A leading international mining group was modernizing a 60-year-old Canadian aluminium smelter facility to build an environmentally superior, safer, and more technologically advanced smelter. The customer was seeking compact and economically viable switchgear for 22 bus sections to be installed at eight substation locations within the same facility. Each bus section would be furnished with one or two incomer/tie ways and five feeder ways. Each fault-interrupting way required protection relays and remote trip capability.

The mining group’s switchgear-operating philosophy required one open fault interrupter between the switchgear units, but no specific fault interrupter was defined as the open point. This differed from traditional philosophies, where the normally open point is well defined.

Under these conditions, implementing a protection scheme to accommodate coordination between the fault interrupters in case of a system fault is a challenging task. Moreover, traditional time-current protection schemes cannot provide protection coordination because the fault-current flow can be in either direction depending on which incomer way is feeding the fault based on which tie is closed.

S&C Solution

The customer had heard about S&C’s successful installation and commissioning of Vista Underground Distribution Switchgear at a hospital in Montreal, Quebec, so the mining group decided to visit the site to learn more about the system. After the visit, the customer felt that the solution would be an excellent alternative to what it had seen in switchgear from other companies. They were particularly impressed with the Vista switchgear’s compact size, remote supervisory capability, visible isolation, and faultinterrupting capability.

Remote Supervisory Vista® Switchgear took up 30% less space than metal-clad switchgear, considerably reducing concrete-foundation construction costs.

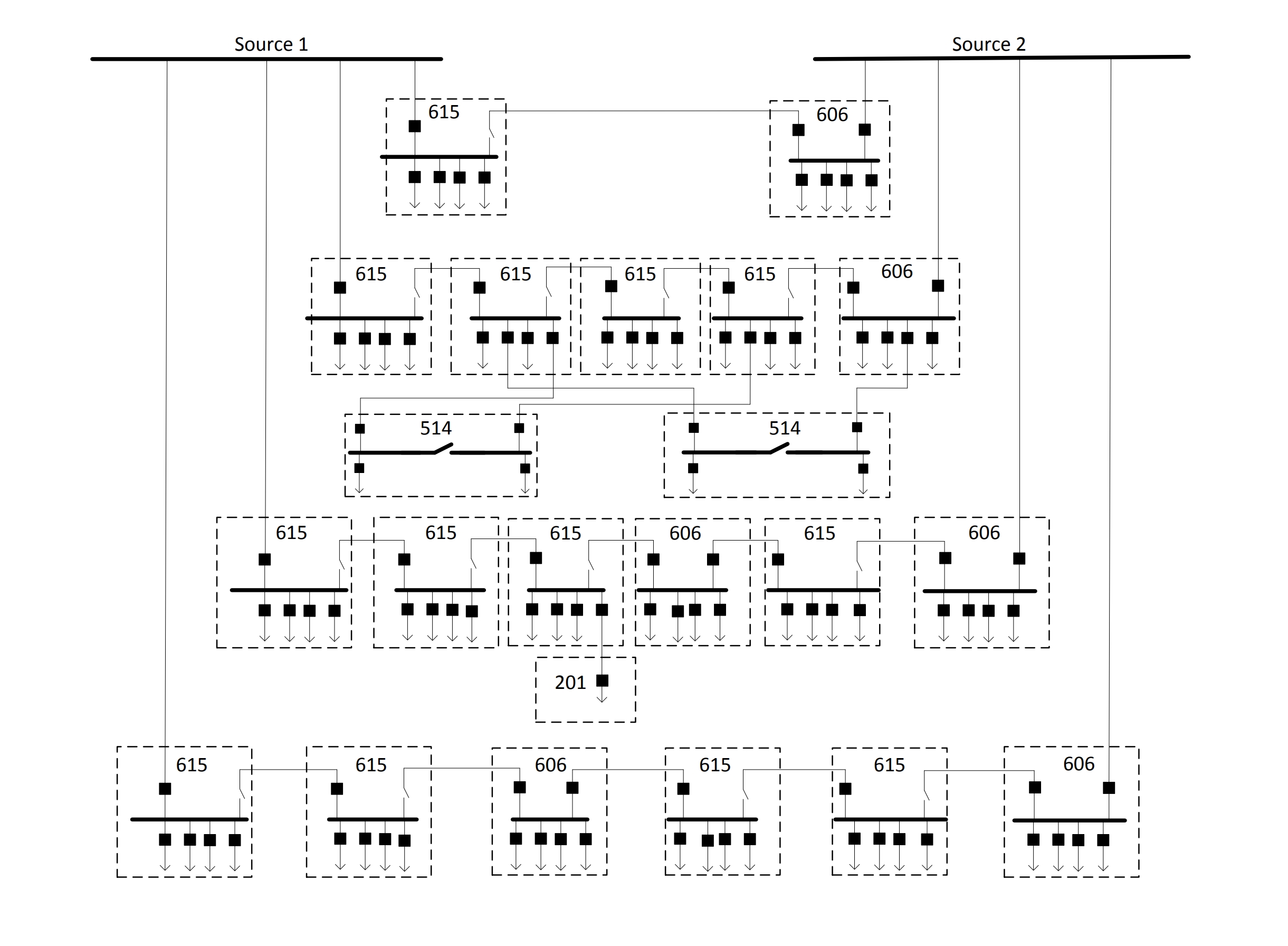

S&C’s sales team and Power Systems Solutions (PSS) engineers convinced the owner and its consultant to proceed with using Vista switchgear. The company chose to deploy 22 Remote Supervisory Vista® Underground Distribution Switchgear units because of the product’s low pro le and novel features. In addition, the mining group chose to use the Vista switchgear’s internal current transformers and bushing-mounted voltage sensors for protection purposes. It also opted to use S&C’s PSS expertise to design the protection-and-control philosophy for its 25-kV electrical system. S&C manufactured various models of 29-kV Vista to protect the various feeders. (Shown in schematic below).

Overall site schematic, showing relative placement and configuration of all 22 Vista switchgear units.

The protection philosophy—based on point-to-point communication between the relays—was deployed to suit the system requirements and to provide required performance under normal operating conditions, as well as during breaker-failure mode. Breaker-failure protection provides an additional layer of protection using an upstream interrupting device if a particular breaker fails to clear a fault. The incomer and tie relays connect via fiber-optic cables. The supervisory control and data-acquisition (SCADA) system located in the electrical room of each substation communicates with the relays via Ethernet ports through the IEC61850 protocol.

S&C implemented the protection scheme for bus and feeder faults using a blocking concept. This concept ensures only the faulted element is isolated, while the protection devices on the healthy sections are blocked from operating in response to a fault.

S&C engineered an isolation scheme as an extension of the protection scheme to isolate a faulted bus by locking open the fault interrupters on both sides of the faulted bus. It implemented the breaker-failure scheme to provide double contingency, thus making the protection design more robust.

At its Toronto facility, S&C conducted Factory Acceptance Testing of the Vista Switchgear to ensure the logic and programming of the electronics would work properly in the field. It confirmed realtime coordination timing by tripping the appropriate interrupter(s) and opening the disconnect switch(es). Site acceptance testing under S&C’s supervision during pre-commissioning activities on site provided an extra layer of design and functionality validation.

Because the mining company took responsibility for maintaining the equipment, S&C provided extensive documentation to support the supplied products and available services. This included equipment layouts, wiring diagrams, input/output lists, schematics, logic diagrams, relay programs, CID les, and operation and maintenance manuals.

Valued Outcome

Both the owner and its consultant were very pleased with the outcome of the project.They were particularly impressed with S&C’s engineering behind the protection scheme. 606 By opting for S&C’s pad-mounted Vista Switchgear instead of metal-clad switchgear, the size of each unit dropped by almost 30%. This smaller footprint resulted in the project being able to save a signi cant amount of money on construction of concrete foundations for the switchgear. S&C successfully completed the project design and engineering on time and within budget. S&C’s Remote Supervisory Vista switchgear, along with the protection-and-control scheme, provided an ideal solution to modernize the smelter’s switchgear facility.

Contact us to learn more.

Request InformationExpert

S&C Electric Company

Publication Date

September 14, 2015