Multiple types of switchgear are available for switching and protecting circuits on utility distribution systems and within commercial and industrial (C&I) facilities. Although metal-clad switchgear and pre-engineered metal-enclosed switchgear are common choices, such switchgear creates challenges from an operations and maintenance (O&M) perspective or lacks the customization utilities or C&I facilities may need for specific application needs.

However, another customizable, low-maintenance, and robustly designed switchgear alternative exists to ease the challenges posed by metal-clad switchgear and pre-engineered metal-enclosed switchgear: S&C's Custom Metal-Enclosed Switchgear.

A Custom Solution

S&C’s Custom Metal-Enclosed Switchgear mitigates the challenges of metal-clad switchgear and pre-engineered metal-enclosed switchgear. Custom Metal-Enclosed Switchgear’s simple construction and installation requirements contribute to a low initial cost compared to metal-clad switchgear. Additionally, the product’s robust design makes it dependable, meaning it requires minimal maintenance over time—further reducing overall O&M costs. Designed to be a perfect fit for unique C&I or utility applications, Custom Metal-Enclosed Switchgear is the best choice to improve reliability.

Product Overview

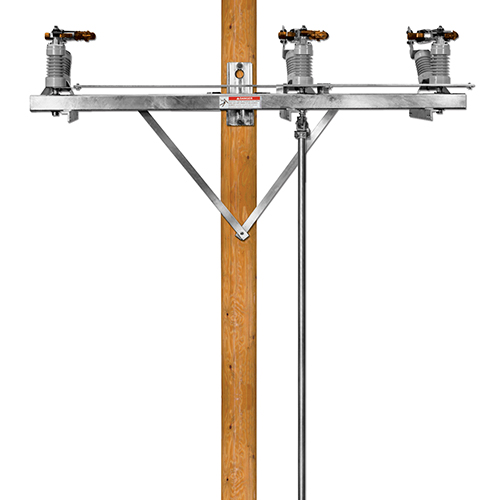

Custom Metal-Enclosed Switchgear incorporates interrupter switches and power fuses in durable enclosures and is tailored to meet specific indoor or outdoor distribution system needs. Available in ratings of 4.16 kV, 13.8 kV, 25 kV, 34.5 kV, and 46 kV, the switchgear is ideal for applications with unique requirements, such as uncommon switchgear bay layouts.

Advantages

Custom Metal-Enclosed Switchgear can be customized to fit your specific application requirements while reducing maintenance costs and improving reliability.

Highly Customizable

Gear is configured to meet any system or application need

Low Maintenance

Switches and fuses never need adjusting, programming, or dielectric testing

Resilient Design

Utility-grade design withstands time and the elements

Hassle-Free Installation

Preassembled and simpler construction requirements

Lower Total Cost of Ownership

Lower up-front and maintenance costs than metal-clad switchgear

Improved Reliability

Fuses offer faster fuse-clearing time and reduce system stress compared to circuit breakers

Features

Custom Metal-Enclosed Switchgear can be customized to fit your specific application requirements while reducing maintenance costs and improving reliability.

Arc-Resistant Option

Operators and adjacent equipment protected from arc-flash events

Lightweight Design

Easier transport, assembly, and installation

Multiple Fuse Choices

Choose from S&C SM or SML Power Fuses or Fault Fiter® Electronic Power Fuses

Single-Phase Load Protection

Fuses isolate only faulted phases of feeders

Three-Phase Load Protection

Open-phase detection or overcurrent relays are available

Sophisticated Source-Transfer Capabilities

Automatic power transfer from multiple sources

Corrosion-Resistant Enclosure

Steel enclosure is protected against rain and corrosion using the state-of-the-art Ultradur® II Outdoor Finish

Case Studies

Featured customer successes achieved using Custom Metal-Enclosed Switchgear:

Flexibility and Custom-Design Expertise Provide Solution for National Laboratory

Read Case StudyS&C Designs Custom Metal-Enclosed Switchgear for Airport

Read Case StudyS&C Reduces Cost and Improves Safety at a Movie Studio

Read Case StudyProduct Details

Custom Metal-Enclosed Switchgear is ideal for:

- Complex automatic source-transfer schemes with two or more incoming power sources, multiple split-bus sections, or ring-bus arrangements

- Applications with cold- or hot-sequence metering

- Applications with special installation requirements, such as transformer primary unit substations, and those requiring special-purpose components, such as grounding switches, control power transformers, metering panels, or capacitors for power-factor correction

- New or retrofit applications requiring uncommon switchgear layouts or having unique installation constraints, such as “U-shaped” configurations

(On mobile, swipe left for remaining ratings information.)

| kV | Amperes | Components | Short Circuit, Amperes RMS, Sym. |

|||||

|---|---|---|---|---|---|---|---|---|

| Nom. | Max | BIL | Main Bus | Load Dropping |

Type | Detail | Amperes Max. | |

| 4.16 | 4.8 | 60 | 600 | NA | Fuse | SM-4Z | 200E | 17 200 |

| NA | Fuse | SM-40 | 400E | 25 000 | ||||

| NA | Fuse | SM-5S | 400E | 37 500● | ||||

| NA | Fuse | Fault-Fiter | 600 | 40 000 | ||||

| 600 | Switch | Mini-Rupter | 600 | 25 000 | ||||

| 4.16 | 4.8 | 60 | 1200 | NA | Fuse | SM-4Z | 200E | 17 200 |

| NA | Fuse | SM-40 | 400E | 25 000 | ||||

| NA | Fuse | SM-5S | 400E | 37 500● | ||||

| NA | Fuse | Parallel SM-5S |

720E | 37 500● | ||||

| NA | Fuse | Fault-Fiter | 600 | 40 000 | ||||

| NA | Fuse | Parallel Fault-Fiter |

1200 | 40 000 | ||||

| 600 | Switch | Mini-Rupter | 600 | 25 000 | ||||

| 1200 | Switch | Alduti-Rupter | 1200 | 38 125 | ||||

| 13.8 | 17.0 | 95 | 600 | NA | Fuse | SM-4Z | 200E | 12 500 |

| NA | Fuse | SM-20 | 200E | 14 000 | ||||

| NA | Fuse | SM-40 | 400E | 25 000 | ||||

| NA | Fuse | SM-5S | 400E | 25 000 | ||||

| NA | Fuse | SM-5SS | 400E | 34 000 | ||||

| NA | Fuse | Fault-Fiter | 600 | 40 000 | ||||

| 600 | Switch | Mini-Rupter | 600 | 25 000 | ||||

| 13.8 | 17.0 | 95 | 1200 | NA | Fuse | SM-4Z | 200E | 12 500 |

| NA | Fuse | SM-20 | 200E | 14 000 | ||||

| NA | Fuse | SM-40 | 400E | 25 000 | ||||

| NA | Fuse | SM-5S | 400E | 25 000 | ||||

| NA | Fuse | Parallel SM-5S |

720E | 25 000 | ||||

| NA | Fuse | SM-5SS | 400E | 34 000 | ||||

| NA | Fuse | Fault-Fiter | 600 | 40 000 | ||||

| NA | Fuse | Parallel Fault-Fiter |

1200 | 40 000 | ||||

| 600 | Switch | Mini-Rupter | 600 | 25 000 | ||||

| 1200 | Switch | Alduti-Rupter | 1200 | 38 125 | ||||

| 25 | 29■ | 125 | 600 | NA | Fuse | SM-4Z | 200E | 9 400▲ |

| NA | Fuse | SM-20 | 200E | 12 500 | ||||

| NA | Fuse | SM-5S | 400E | 20 000 | ||||

| NA | Fuse | SM-40 | 400E | 20 000 | ||||

| NA | Fuse | Fault-Fiter | 600 | 40 000 | ||||

| 400 | Switch | Mini-Rupter | 600 | 20 000 | ||||

| 25 | 29 | 150 | 600 | NA | Fuse | SM-4Z | 200E | 9 400▲ |

| NA | Fuse | SM-5S | 400E | 20 000 | ||||

| NA | Fuse | SM-40 | 400E | 20 000 | ||||

| NA | Fuse | Fault-Fiter | 600 | 40 000 | ||||

| 600 | Switch | Alduti-Rupter | 600 | 17 500 | ||||

| 25 | 29■ | 125 | 1200 | NA | Fuse | SM-4Z | 200E | 9 400▲ |

| NA | Fuse | SM-20 | 200E | 12 500 | ||||

| NA | Fuse | SM-5S | 400E | 20 000 | ||||

| NA | Fuse | SM-40 | 400E | 20 000 | ||||

| NA | Fuse | Fault-Fiter | 600 | 40 000 | ||||

| NA | Fuse | Parallel Fault-Fiter |

1200 | 40 000 | ||||

| 400 | Switch | Mini-Rupter | 600 | 20 000 | ||||

| 1200 | Switch | Alduti-Rupter (34.5 kV 1200 Amp) |

1200 | 17 500 | ||||

| 25 | 29■ | 150 | 1200 | NA | Fuse | SM-4Z | 200E | 9 400▲ |

| NA | Fuse | SM-5S | 400E | 20 000 | ||||

| NA | Fuse | SM-40 | 400E | 20 000 | ||||

| NA | Fuse | Fault-Fiter | 600 | 40 000 | ||||

| NA | Fuse | Parallel Fault-Fiter |

1200 | 40 000 | ||||

| 1200 | Switch | Alduti-Rupter (34.5 kV 1200 Amp) |

1200 | 17 500 | ||||

| 34.5 | 38 | 150 | 600 | NA | Fuse | SM-4Z | 200E | 6 250 |

| NA | Fuse | SM-20 | 200E | 8 450 | ||||

| NA | Fuse | SM-5S | 300E | 17 500 | ||||

| 600 | Switch | Alduti-Rupter | 600 | 17 500 | ||||

| 34.5 | 38 | 200 | 600 | NA | Fuse | SM-4Z | 200E | 6 250 |

| NA | Fuse | SM-5S | 300E | 17 500 | ||||

| 600 | Switch | Alduti-Rupter | 600 | 17 500 | ||||

| 34.5 | 38 | 150 | 1200 | NA | Fuse | SM-4Z | 200E | 6 250 |

| NA | Fuse | SM-20 | 200E | 8 450 | ||||

| NA | Fuse | SM-5S | 300E | 17 500 | ||||

| 1200 | Switch | Alduti-Rupter (600 Amp) |

600 | 17 500 | ||||

| 1200 | Switch | Alduti-Rupter (1200 Amp) |

900 | 17 500 | ||||

| 46 | 48.3 | 250 | 600 | 600 | Switch | Alduti-Rupter Switch | 600 | 18 800 |

| 46 | 48.3 | 350 | 1200 | 1200 | Interrupter | Series 2000 Circuit Switcher | 1200 | 40 000♦ |

| 46 | 48.3 | 350 | 600 | NA | Interrupter | Trans-Rupter II® Transformer Protector | 600 | 25 000 |

| 46 | 48.3 | 250 | 600 | NA | Fuse | SMD-2C | 300E | 31 500 |

60-Hz Ratings ①

① The ratings shown here are for individual bays. The rating for the entire assembly is the same as the lowest-rated bay. For 2000-A and 3000-A main-bus ratings, please contact S&C.

NA Not applicable.

● Rating based on 4.16-kV refill. Rating is 27 000 amperes for a 7.2-kV refill.

■ The Max rating is reduced to 27 kV if using fuse types SM-4Z, SM-20, or SM-5S.

▲ Rating is 12 500 amperes on solidly grounded circuit with single-conductor concentric neutral cable or bus connection to transformer.

♦ This rating is for transformer switching and protection only. For other applications, short circuit rating is 25 000 amperes RMS, Sym.

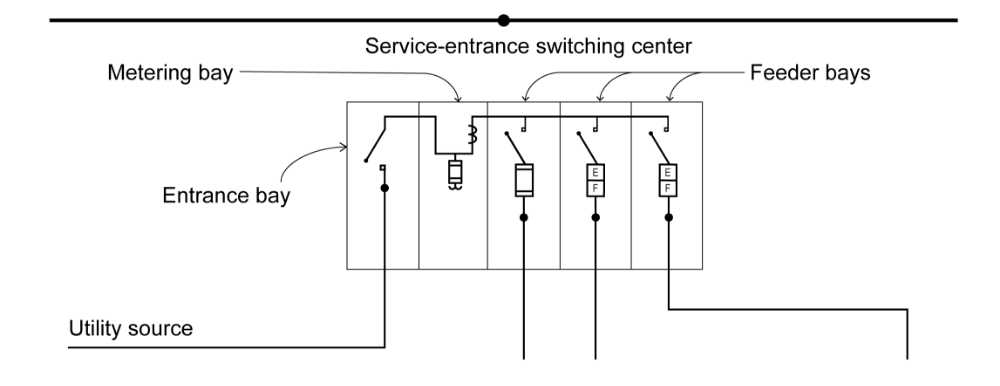

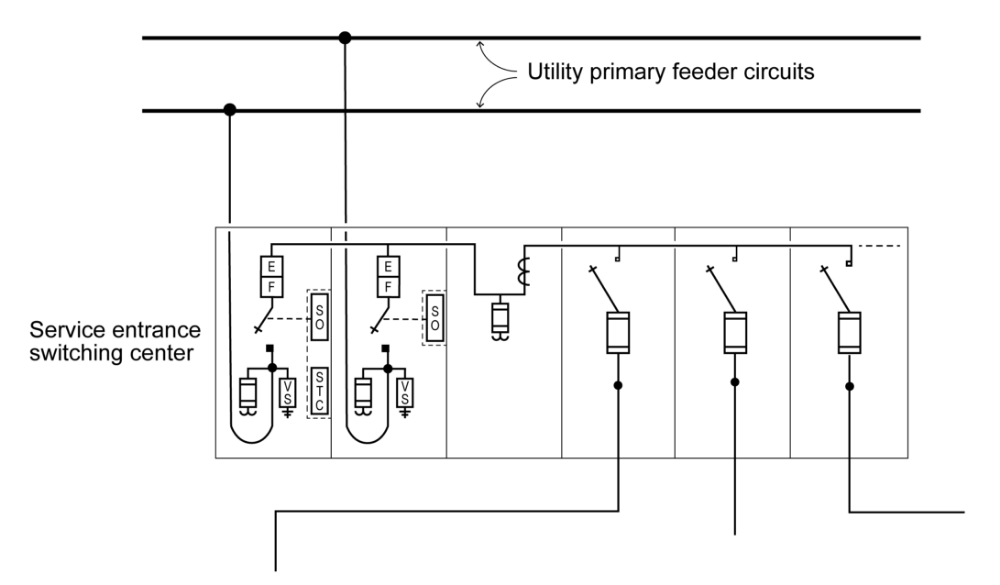

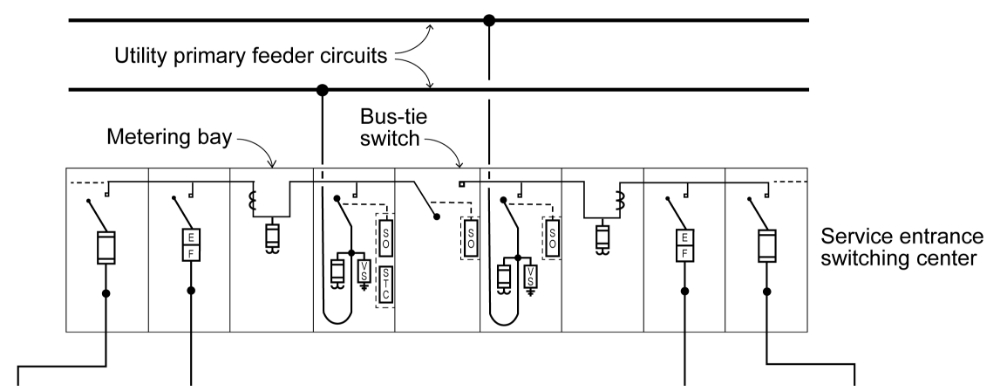

The basic arrangements shown below are often combined to handle even the most complex distribution system needs. Other circuit designs are possible to fit specific needs. For example, Custom Metal-Enclosed Switchgear and Vista® Underground Distribution Switchgear modules can be combined to create System VI™ Switchgear

Radial System

A radial system is the simplest system and is economical, permitting extensive use of dedicated radial circuits. The direct circuitry facilitates quick location and repair of faulted circuits. Segmentation of a distribution system with multiple radial circuits limits the extent of service interruption caused by faults. In this example, the service-entrance bay of the S&C’s Custom Metal-Enclosed Switchgear is provided with electronic power fuses to achieve full coordination with the upstream protective device.

Common-Bus Primary-Selective

S&C’s Custom Metal-Enclosed Switchgear ensures a higher level of service continuity. Two utility sources—one source preferred the other alternate—supply power to the metal-enclosed switchgear. A power-operated interrupter switch for each source plus a source-transfer control affects the automatic two-way transfer in primary-selective switchgear. Interrupter switches with power fuses switch and protect the load circuits; in this example, two are manually operated.

Split-Bus Primary-Selective

S&C’s Custom Metal-Enclosed Switchgear allows large in-plant systems to be supplied power through one switching center because both utility sources are fully used under normal operation, with the two source-interrupter switches closed and the bus-tie switch open. Each source, in effect, is the preferred source for its bus section and the alternate source for the other bus section.

Switches and Fuses

- Mini-Rupter® Switch—rated through 600 amperes continuous and interrupting

- Alduti-Rupter® Switch—rated through 1200 amperes continuous and interrupting are also available

- Type SM-40 Power Fuse—rated 400 amperes max continuous (Other Type SM power fuses are available in ratings from 200 through 720 amperes max continuous. Fuses are offered in a wide variety of time-current characteristic (TCC) curves for optimal coordination and maximum protection. The TCC curves are precise and permanently accurate.)

- Fault Fiter® Electronic Power Fuses—rated through 600 amperes max continuous (They have exceptional TCC versatility and higher continuous current ratings than previously available in fuses.)

Switch Operators and Controls

- Type MS Switch Operators provide high-speed automatic Trip Open operation of Mini-Rupter Switches, and the interrupting time is 4 cycles. Type MS operators are available in a choice of manual or automatic Trip Closed operation.

- Micro-AT® Source-Transfer Controls minimize interruptions resulting from the loss of one source, and transfer is achieved in as little as 20 to 25 cycles. Available with a wide choice of options.

- Type ZSD Overcurrent Relays, applied on individual load feeders, provides three-phase isolation after a downstream fault has been detected and cleared. Superior to ordinary overcurrent relays, they can distinguish between fault current and transformer magnetizing inrush current.

Also available:

- AS-30 Switch Operators for Alduti-Rupter Switches.

- Open-Phase Detectors – Type SPD for protection of three-phase load circuits from open phase conditions.

Arc-resistant Custom Metal-Enclosed Switchgear is readily configured in circuit arrangements that make power system planning and design easy.

Combines the rugged features of Custom Metal-Enclosed Switchgear with additional measures needed to withstand the effects of internal arcing faults.

The enhanced design has successfully passed the rigorous certification testing required by Canadian Standard EEMAC G14.1. This standard addresses the effects of internal arcing fault conditions, including overpressure acting on covers, doors, and inspection windows. It also covers the thermal effects of the arc and verification the arc does not burn through external walls of the enclosure.

Ratings of Currently Available Arc-Resistant Switchgear Bays

| kV | Amperes, RM | |||

|---|---|---|---|---|

| Nominal | Maximum | BIL | Continuous | Short-Circuit, Symmetrical |

| 4.16 – 13.8 | 17 | 95 | 600 | 40 000 |

| 25 | 29 | 125 | 600 | 20 000 |

| 34.5 | 38 | 150 | 600 | 17 500 |